Cookie Privacy Preferences

We utilize essential cookies to ensure our website operates effectively and remains secure. Additionally, we'd like to request your permission to use optional cookies. These are intended to enhance your browsing experience by offering personalized content, displaying advertisements that are relevant to you, and helping us to further refine our website.

Choose "Accept all cookies" to agree to the use of both essential and optional cookies. Alternatively, select "Let me see" to customize your preferences.

Privacy Preference Centre

Our website utilizes cookies to enhance your browsing experience and to present you with content tailored to your preferences on this device and browser. Below, you will find detailed information about the function of cookies, enabling you to make informed choices about which cookies you wish to accept. Please note that disabling certain cookies might impact your user experience on our site. It's important to remember that cookie preferences need to be set individually for each device and browser you use. Clearing your browser's cache may also remove your cookie settings. You have the freedom to modify your cookie preferences at any point in the future.

For a comprehensive understanding of our use of cookies, please refer to our complete cookies policy.

These cookies are needed for the website to work and for us to fulfil our contractual obligations. This means they can't be switched off. They enable essential functionality such as security, accessibility and live chat support. They also help us to detect and prevent fraud. You can set your browser to block or alert you about these cookies, but it means some parts of the site won't work.

These cookies allow us to measure and improve the performance of our site. They help us to know how popular pages are, and to see how visitors move around the site. If you don't allow these cookies, we won't know when you've visited our site, and we won't be able to monitor its performance.

These cookies enable us to provide enhanced functionality and personalisation. They may be set by us or by third party providers whose services we've added to our pages. If you don't allow these cookies, some or all of these services may not work properly.

These cookies collect information about your browsing habits to show you personalised adverts. They may be used to build a profile of your interests and show you relevant adverts on other sites. They don't store directly personal information, but are based on uniquely identifying your browser and internet device. If you don't allow these cookies, the adverts you see will be less relevant.

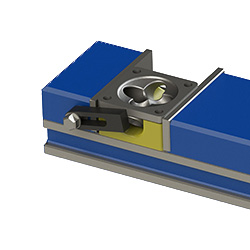

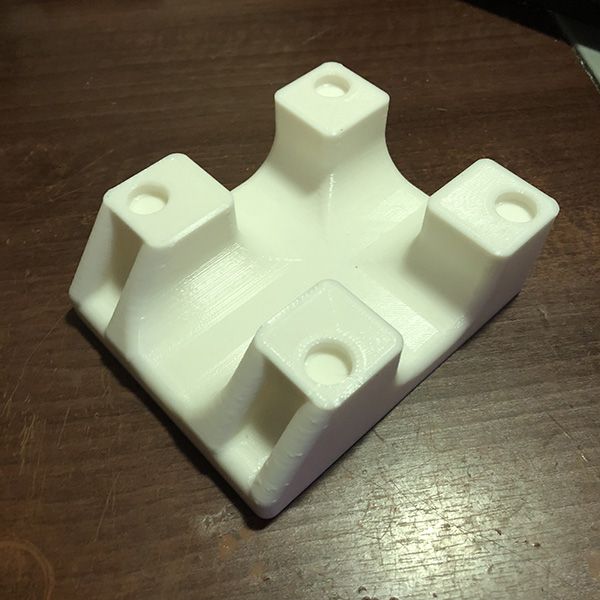

Easton3D's Chris Easton has over 25 years experience of mechanical production engineering ranging from R & D Machinist through to Production Engineer, In a wide variety of industries including High Vacuum and Motorsport development.

Drawing on this knowledge Easton3D can offer this new Fixtures Service. Ideally suited to the "One Off" Prototype customers and also for use on small batch production runs.

The Key benefits and cost savings this service can offers:

We create the design to suit your requirements

3D printed with high density infill to give maximum rigidity

More surface area covered to reduce the chances of ringing

If you have any questions or you would like to send us some details to give you a free

quote, please use the contact us link below

Change currency

Change currency